[References]

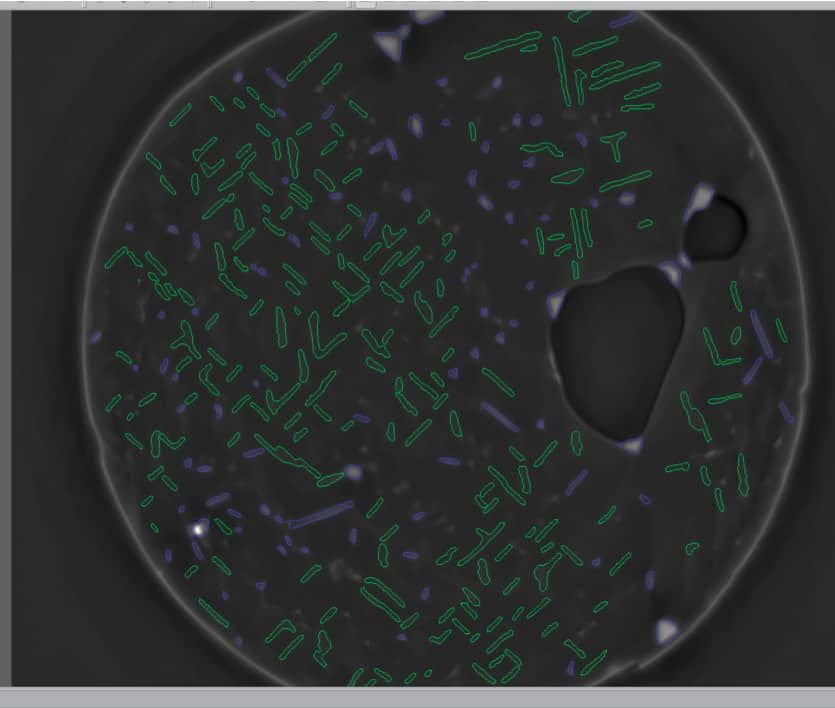

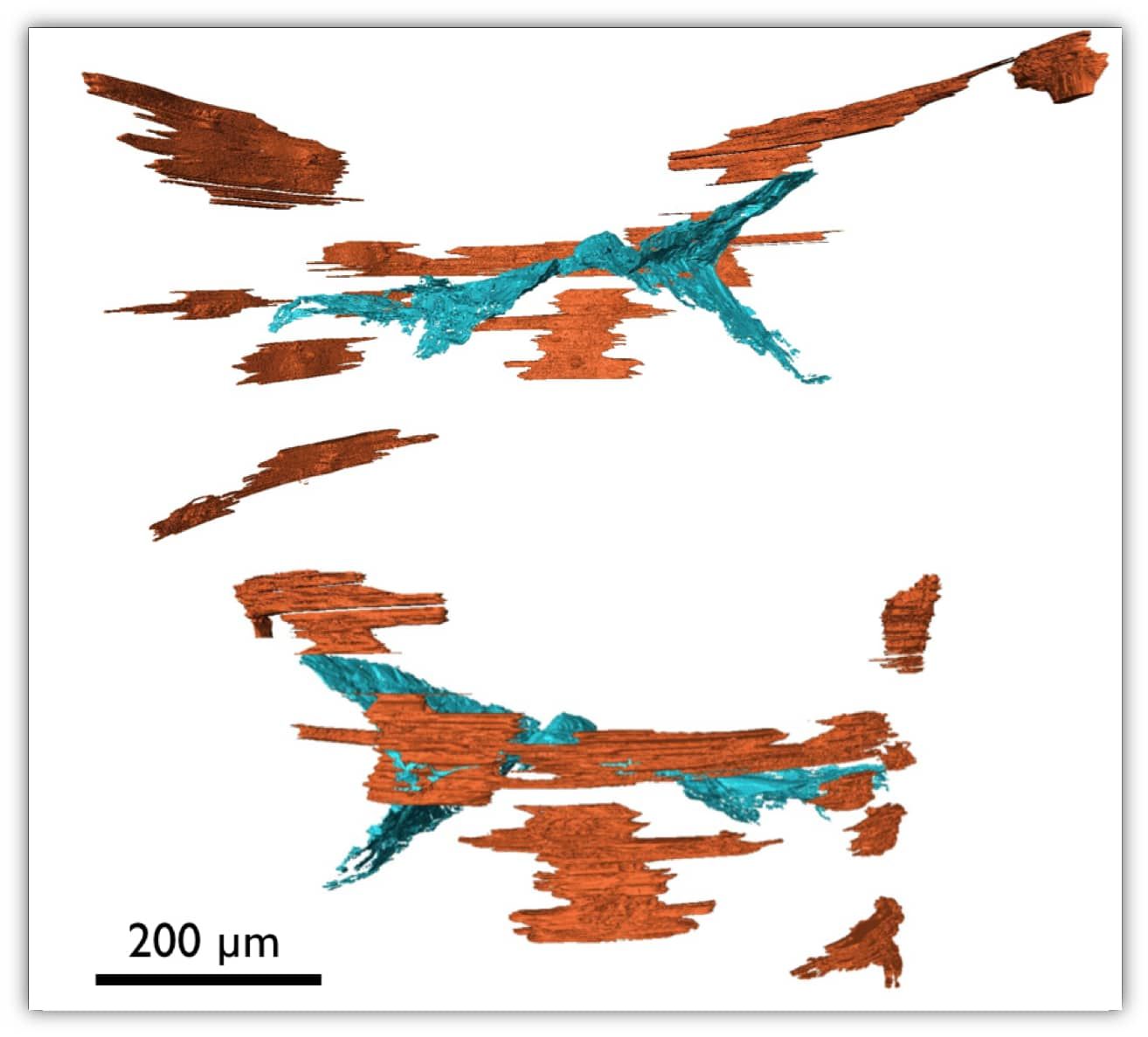

[1] Singh, Sudhanshu S., et al. "Three Dimensional Microstructural Characterization of Nanoscale Precipitates in AA7075-T651 by Focused Ion Beam (FIB) Tomography." Materials Characterization, vol. 118, 01 Aug. 2016, pp. 102-111. EBSCOhost, doi:10.1016/j.matchar.2016.05.009.

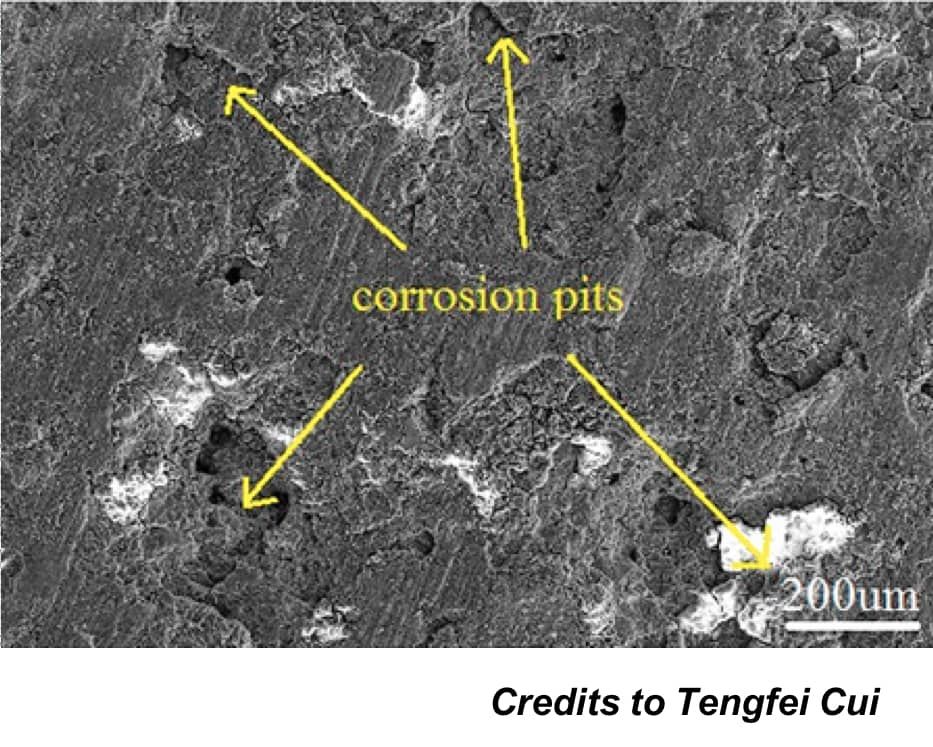

[2] Jin-yang, Jiang, et al. "Pitting Corrosion Behaviour of New Corrosion-Resistant Reinforcement Bars in Chloride-Containing Concrete Pore Solution." Materials (1996-1944), vol. 10, no. 8, Aug. 2017, pp. 1-21. EBSCOhost, doi:10.3390/ma10080903.

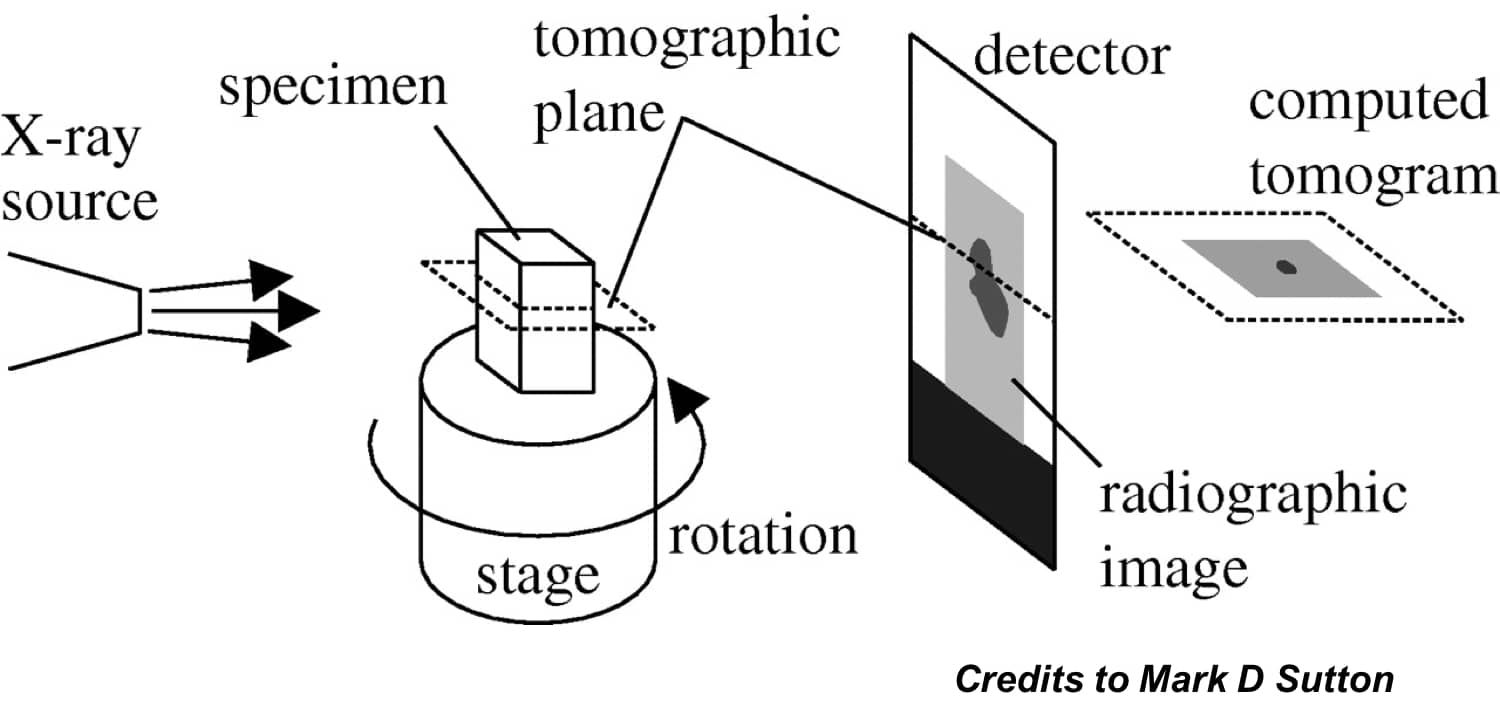

[3] Mark D., Sutton. "Tomographic Techniques for the Study of Exceptionally Preserved Fossils." Proceedings: Biological Sciences, no. 1643, 2008, p. 1587. EBSCOhost, doi:10.1098/rspb.2008.0263.

[4] Cui, Tengfei, et al. "Effect of Pre-Corrosion and Corrosion/Fatigue Alternation Frequency on the Fatigue Life of 7B04-T6 Aluminum Alloy." Journal of Materials Research, vol. 31, no. 24, n.d., pp. 3869-3879. EBSCOhost, search.ebscohost.com/login.aspx?direct=true&db=edswsc&AN=000392859000007&site=eds-live.