ME231A/EE220B Final Project

Berkeley || Fall '17

ME231A/EE220B Final Project

Berkeley || Fall '17

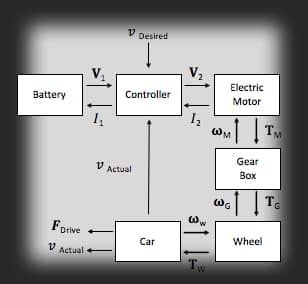

Dynamic Programing Approach

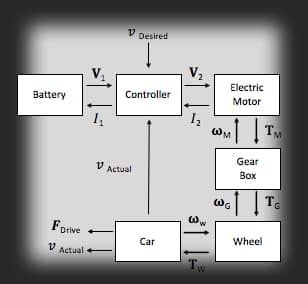

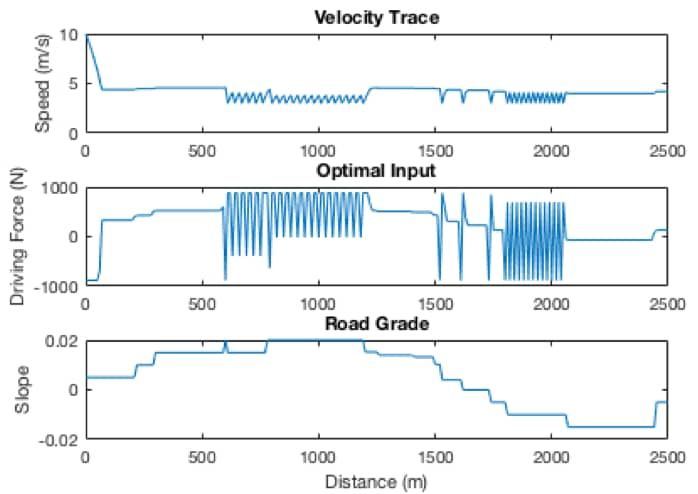

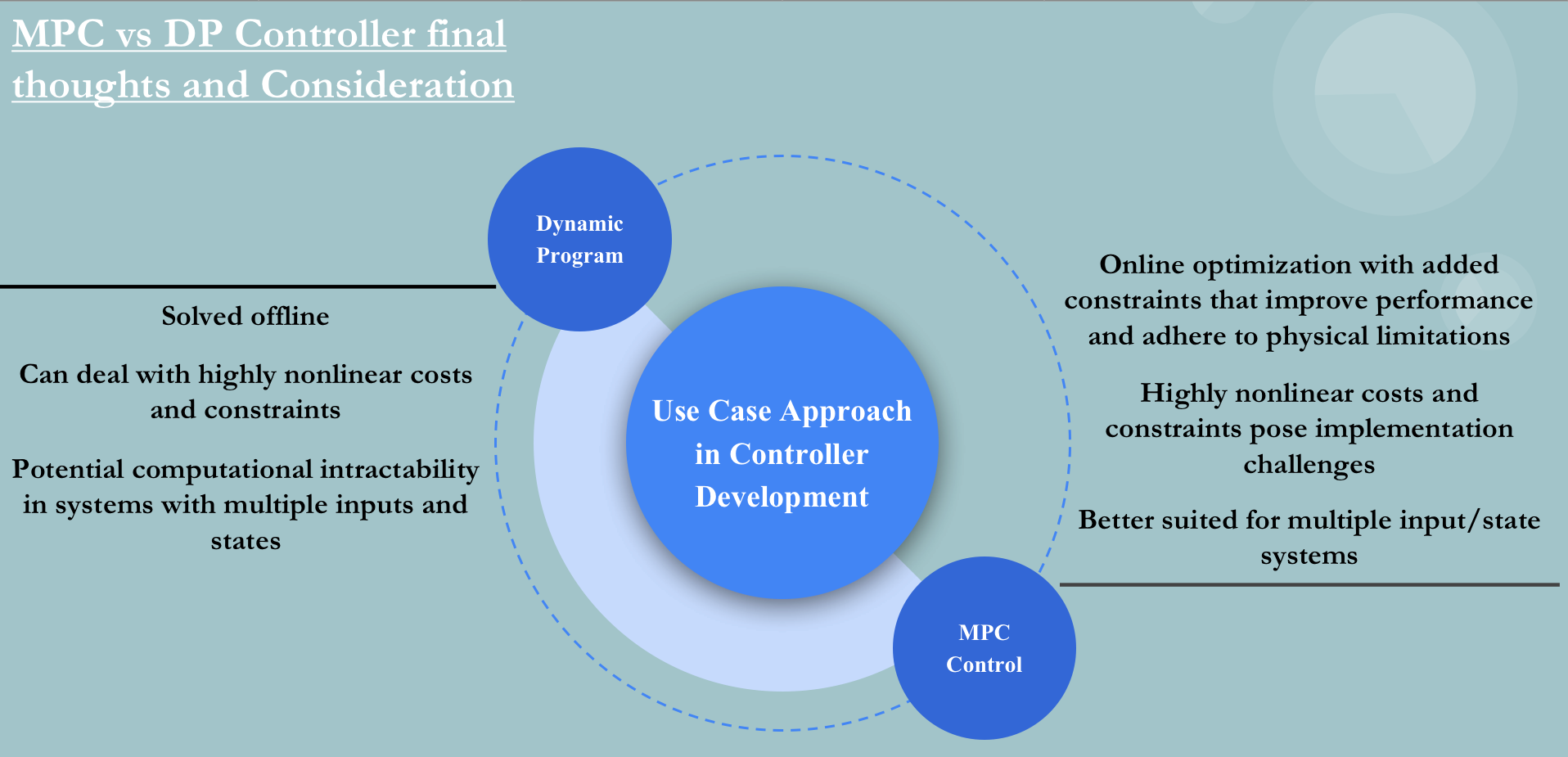

The DP approach involves discretizing the state (i.e., speed, v), input (i.e., driving force Fdrive), and position spaces to generate a look-up table that correlates the measured values at a given position to the optimal input. Although it can work with nonlinear costs and constraints, there is potential computational intractability in systems with multiple inputs and states. Furthermore these approaches tend to computationally heavy and therefore time consuming. The approach does guarantee the user to calculate the entire solution space, which is helpful for offline calculation needs.

Model Predictive Controllers

The MPC approach first solves an optimal control problem over a chosen prediction horizon given a measured position, The first input in this sequence is then applied to the system and the new state of the system becomes the initial state for the next optimal control problem. This pattern is then repeated over the entire length of the chosen roadway. One significant issue is dealing with nonlinearity in constraints or cost. For our study dealing with the nonlinearity of efficiency become quite the challenge. MPC are however, very capable of modeling multiple input/state systems.

Challenges seen in study

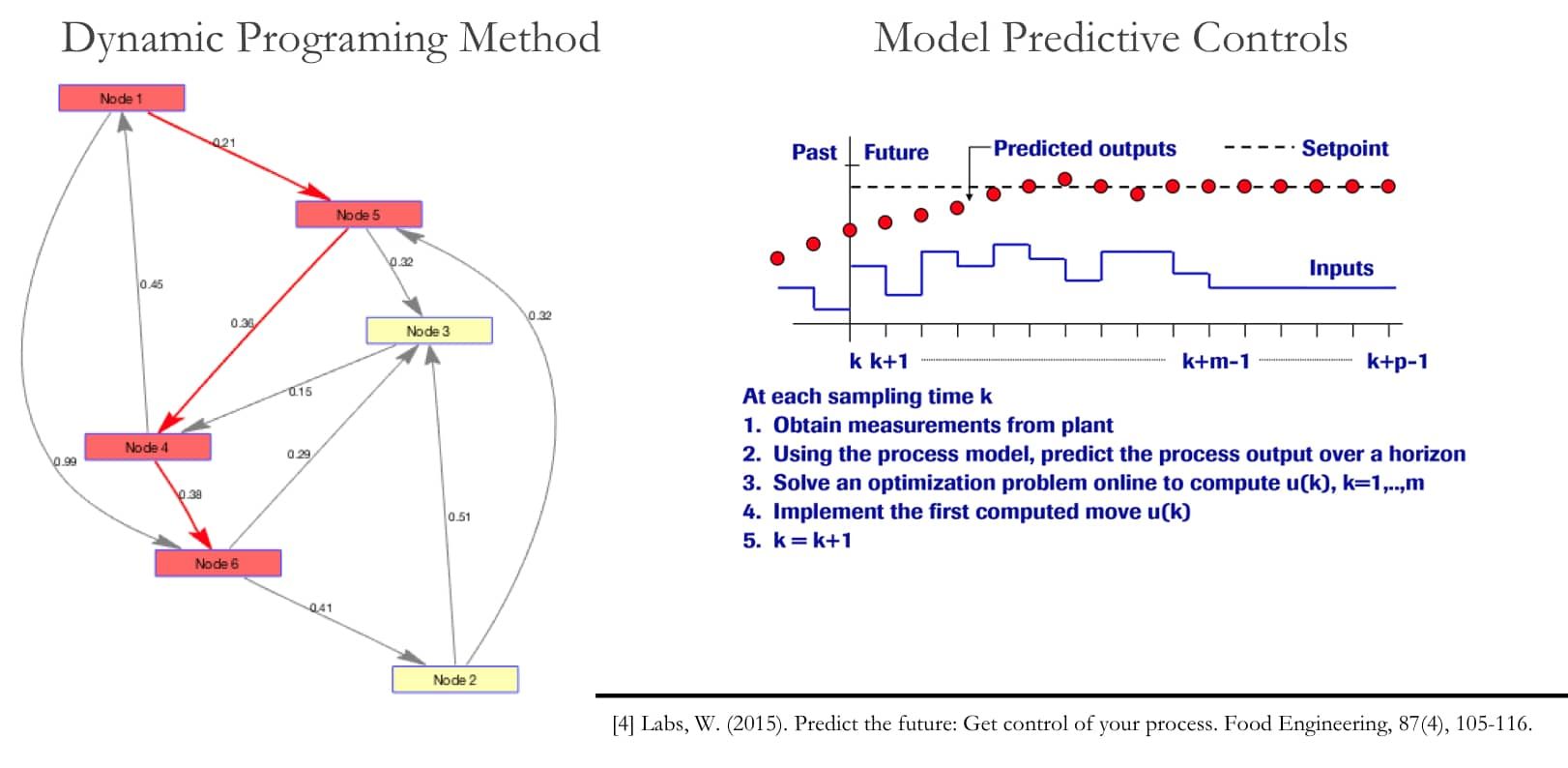

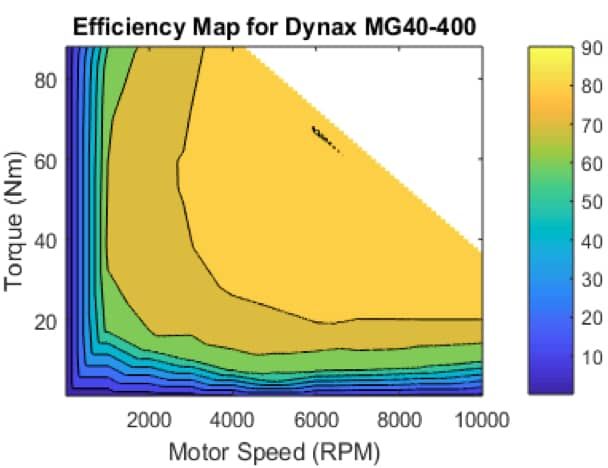

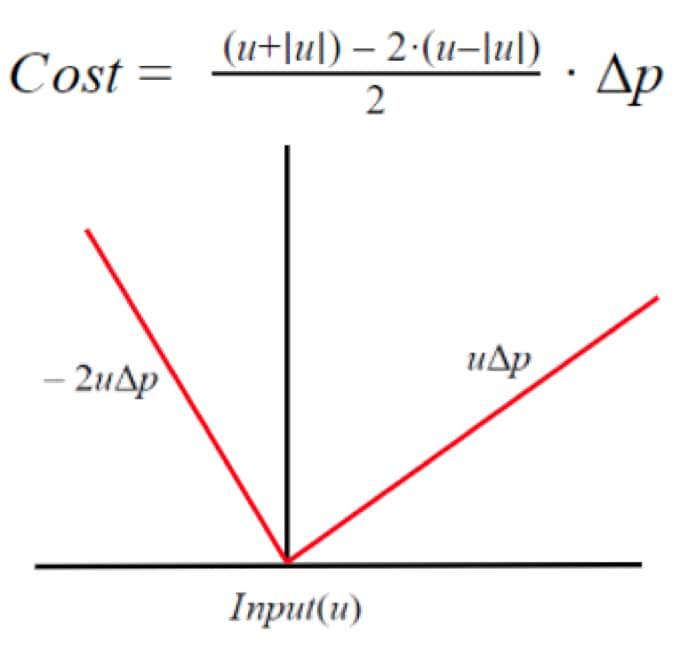

Issue 1: One challenge we had encountered while building the code was handeling the nonlinear nature of the powertrain efficiency. Several methods were used to combat the issue. Interpolated Lookup Tables using MATLAB's "interpn" function. Estimation via High Order Polynomial, and even just ignoring efficiency altogether. One method that we could have employed is using an isoefficiency curve to approximate one general efficiency.

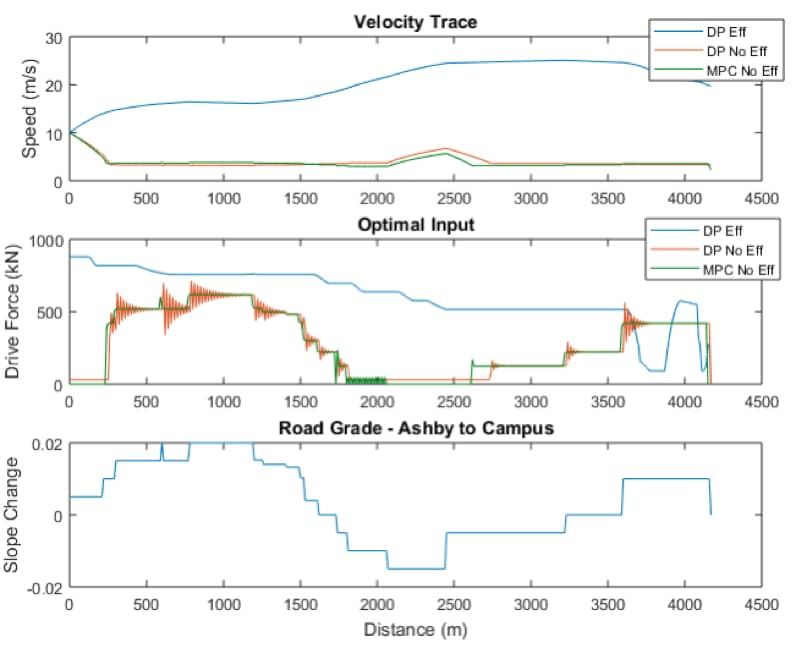

Using the DP appraoach, we were able to encorporate the efficiency of the motor. As a result, we see more realistic driving patterns as the user goes slowly up the incline, and speeds up at the end. Without taking efficiency considerations, the DP solution and MPC solution look very similar. We see that use of braking is still incorporated to minimize the cost, although this behavior is not a practical real life scenario. Furthermore, when efficiency is not considered, the motot is most likely not fully transferring power. Overall the system uses roughly 1055.55 watt-hours for the solution while taking efficiency considerations, and 322.22 watt-hours for η = 1.

The MPC approach could only be approximated with η =1. The nonlinear nature of the efficiency function made modeling this feature an issue, given our knowledge of building MPC models. Overall MPC was computing similar results when compared to DP. The model predicted that the overall route would need 430.55 watt-hours.

Choose from the large selection of latest pre-made blocks - full-screen intro, bootstrap carousel, content slider, responsive image gallery with lightbox, parallax scrolling, video backgrounds, hamburger menu, sticky header and more.

Sites made with Mobirise are 100% mobile-friendly according the latest Google Test and Google loves those websites (officially)!

Mobirise themes are based on Bootstrap 3 and Bootstrap 4 - most powerful mobile first framework. Now, even if you're not code-savvy, you can be a part of an exciting growing bootstrap community.

Choose from the large selection of latest pre-made blocks - full-screen intro, bootstrap carousel, content slider, responsive image gallery with lightbox, parallax scrolling, video backgrounds, hamburger menu, sticky header and more.

Future Work & Recommendations

Some of the limitations of our study came with our understanding of properly implementing nonlinearity. Thus future work should look into exploring and implementing MPC with multi-state and input systems with more advanced non-linear optimization tools. Furthermoer, our system held a lot of assumptions that have may not translate well into a "real" word system. Thus accounting for process noise, exogenous disturbances via “Robust” or “Stochastic” model predictive control approaches could be beneficial for future study.